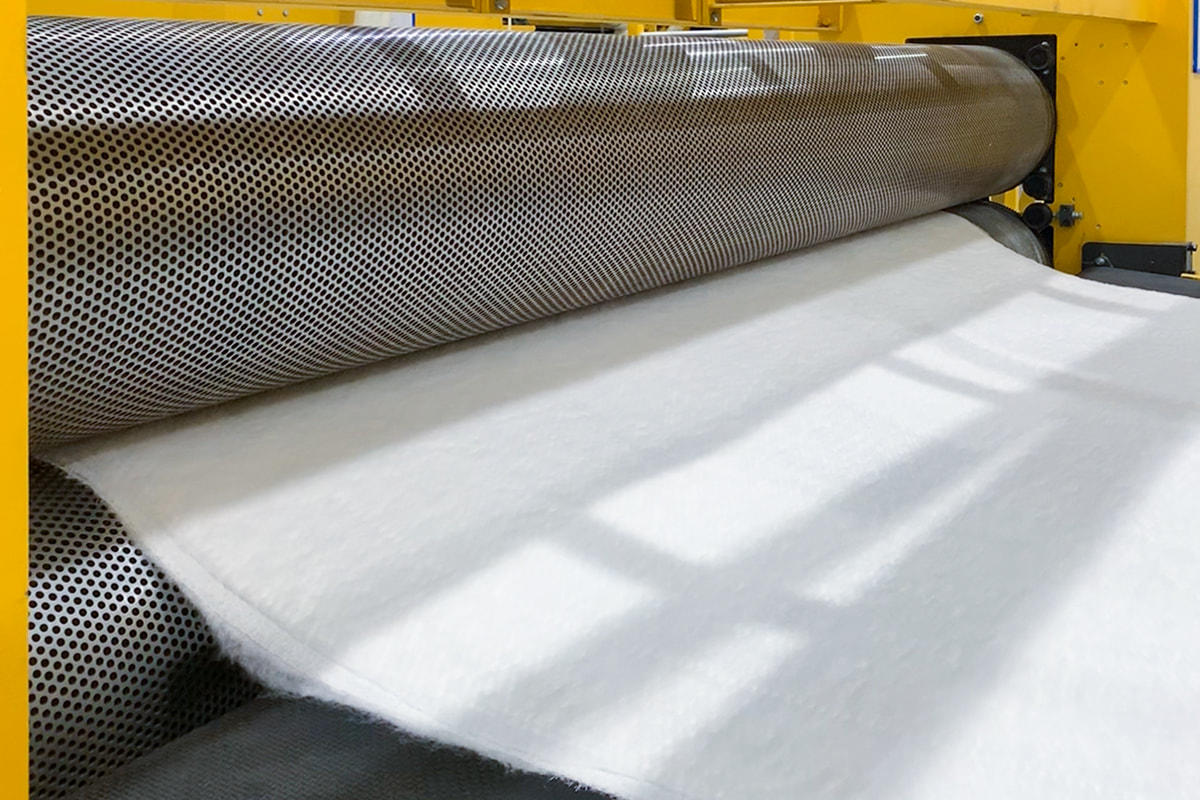

Non-woven fabric manufacturing machine is a kind of equipment widely used in the production of non-woven fabric products. Its production efficiency is affected by many factors, among which the type and quality of raw materials is one of the key factors. High-quality raw materials can not only improve production efficiency, but also reduce equipment failure rates, thereby bringing higher economic benefits to enterprises.

The type of raw materials has an important impact on the production efficiency of nonwoven fabric making machines. Commonly used raw materials in the production process of non-woven fabrics include polypropylene, polyester, viscose fiber, etc. Different kinds of raw materials have different physical and chemical properties, which will affect the production process of nonwoven fabric making machines. For example, polypropylene has good thermal stability and tensile strength and is suitable for high-speed production processes; while polyester fiber has good abrasion resistance and UV resistance and is suitable for the production of special-purpose non-woven products. Therefore, choosing the right type of raw materials is crucial to improving the production efficiency of nonwoven fabric making machines.

The impact of raw material quality on production efficiency cannot be ignored. High-quality raw materials can ensure stability and continuity during the production process, thereby improving production efficiency. For example, high-quality polypropylene fibers have better melting properties and uniformity, which is beneficial for nonwoven fabric making machines to maintain stable melt delivery and fiber distribution during the production process. In addition, high-quality raw materials can also reduce the generation of waste products during the production process and reduce production costs.

High-quality raw materials can also reduce the equipment failure rate of nonwoven fabric making machines. Because high-quality raw materials have good processing properties and stability, there is less wear and damage to equipment during the production process. This helps extend the service life of equipment and reduces the frequency of equipment repairs and replacements, thereby reducing production costs. At the same time, the reduction of equipment failure rate will also help ensure the continuity and stability of the production process and further improve production efficiency.

In order to give full play to the advantages of high-quality raw materials in improving the production efficiency of nonwoven fabric making machines, companies should take the following measures:

1. Strictly control the raw material procurement process to ensure that the quality of purchased raw materials meets production requirements. The quality of raw materials can be ensured by cooperating with reputable suppliers and regularly testing the quality of raw materials.

2. Select the appropriate type of raw materials according to production needs. Enterprises should choose suitable types of raw materials based on the characteristics of their own products and market demand to improve production efficiency and product quality.

3. Strengthen the monitoring and management of the production process. Ensure the stability and continuity of the production process by monitoring key parameters in the production process in real time, such as temperature, pressure, speed, etc.

4. Regularly maintain and maintain the non-woven fabric manufacturing machine to ensure that the equipment is in good working condition. Through timely maintenance and replacement of worn parts, equipment failure rates are reduced and production efficiency is improved.

The production efficiency of nonwoven fabric manufacturing machines is significantly affected by the type and quality of raw materials. Enterprises should pay attention to the selection and quality management of raw materials to improve production efficiency and reduce equipment failure rates, thereby achieving higher economic benefits.