Hot air drying Industry knowledge

How do hot air dryer/oven manufacturers ensure that the hot air generated by the hot air dryer/oven is evenly distributed?

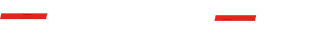

Hot air dryer/oven is an indispensable equipment in modern industrial production, and its performance is directly related to product quality and production efficiency. Among the various performances of the hot air dryer/oven, the uniform distribution of hot air is particularly important. An excellent hot air dryer/oven manufacturer must master a series of technical means to ensure that hot air can be evenly distributed to meet the actual needs of users.

Hot air-through dryer/oven manufacturers will fully consider the characteristics of hot air flow during the design and manufacturing process. Through precise fluid mechanics calculations, they optimized the layout of the hot air circulation system to ensure that the hot air can form a stable and uniform flow within the dryer/oven. At the same time, manufacturers will also carefully design and select key components of the hot air circulation system, such as fans, air ducts, heat exchangers, etc., to ensure that they can work efficiently and stably.

In addition to hardware design, hot air-through dryer/oven manufacturers will also incorporate advanced control strategies into the hot air dryer/oven control system. Through comprehensive control of multiple parameters such as temperature, humidity, and wind speed, the control system can adjust the status of hot air in real time so that it can maintain even distribution during different working stages. In addition, some high-end hot air dryers/ovens are equipped with intelligent diagnosis and optimization functions, which can automatically identify and solve the problem of uneven hot air distribution, further improving the stability and reliability of the equipment.

Hot air-through dryer/oven manufacturers also conduct strict testing and calibration before the equipment leaves the factory. They will conduct long-term operation tests on the hot air dryer/oven under different working conditions, and optimize and adjust the equipment by observing and recording the distribution of hot air. Only equipment that has undergone strict testing and verification will be allowed to leave the factory and be delivered to users.

Hot air dryer/oven manufacturers will also provide complete after-sales service and technical support. They will regularly inspect and maintain the user's hot air dryer/oven to discover and solve possible problems in a timely manner. At the same time, manufacturers will continue to improve and upgrade equipment based on user feedback and needs to better meet market needs.

Hot air-through dryer/oven manufacturers use a series of technical means and service measures to ensure that hot air can be evenly distributed. This not only improves the performance and efficiency of the device, but also brings a better user experience. In the future, with the continuous advancement of technology and the continuous development of the market, I believe that hot air dryer/oven manufacturers will continue to work hard to provide users with more high-quality and efficient products and services.

How do felt heat setting machine suppliers set the heat pressing processing speed of felt heat setting machines to meet different production needs?

In the production process of felt products, heat setting is a crucial process. As the key equipment to realize this process, the felt heat setting machine's hot pressing processing speed setting directly affects the quality and production efficiency of the product. As a supplier of felt heat setting machines, how to accurately set the heat pressing processing speed according to the customer's production needs is the key to ensuring the performance of the equipment and meeting market demand.

Felt heat setting machine suppliers need to have a deep understanding of their customers' production needs. Different felt products have different materials, thickness, density and other characteristics, and have different requirements for hot pressing treatment. For example, thinner felt may require faster heat pressing speeds to ensure production efficiency, while thicker felt may require slower speeds to ensure even heat pressing and avoid deformation. Therefore, suppliers should fully communicate with customers to clarify key information such as product characteristics, specifications, and production volume.

Felt heat setting machine suppliers need to adjust the parameters of the heat setting machine according to the characteristics of the felt. The hot pressing processing speed of the heat setting machine is affected by many factors such as heating temperature, pressure, and hot pressing time. The supplier should set the appropriate heating temperature and pressure according to the material and thickness of the felt. At the same time, through multiple tests and adjustments, the optimal hot pressing time is determined to ensure that the felt can achieve the ideal shaping effect during the hot pressing process.

Felt heat setting machine suppliers should also consider the balance between production efficiency and equipment stability. Increasing the speed of hot pressing can increase production efficiency, but too fast a speed may lead to uneven hot pressing or a decrease in product quality. Therefore, suppliers need to increase the hot pressing speed as much as possible while ensuring product quality. At the same time, by optimizing the equipment structure and improving equipment accuracy, we ensure that the heat setting machine can maintain stable performance during long-term operation.

As a supplier of felt heat setting machines, setting the heat press processing speed is a comprehensive task that requires an in-depth understanding of customer needs, adjustment of equipment parameters, balance of production efficiency and equipment stability, and provision of complete after-sales service and technical support. Only in this way can we ensure that the performance of the equipment is fully exerted, meet the production needs of customers, and win market recognition.