Flushable(Environment friendly)spunlace line Industry knowledge

During the production process, how do wood pulp spunlace production line manufacturers ensure that the wood pulp spunlace production line can evenly distribute and tightly combine wood pulp fibers?

In the manufacturing process of wood pulp spunlace production line, it is crucial to ensure the uniform distribution and tight combination of wood pulp fibers. This is not only related to the operating efficiency of the production line, but also directly affects the quality and performance of the final product. Therefore, as a professional wood pulp spunlace production line manufacturer, we have taken a series of measures to ensure the realization of this goal.

Wood pulp spunlace production line manufacturers focus on the screening and processing of raw materials. High-quality wood pulp fibers are the basis for producing high-quality products. Wood pulp spunlace production line manufacturers strictly control the procurement of raw materials to ensure that the selected wood pulp fibers meet the standards. At the same time, they use advanced processing techniques to improve the dispersion and softness of the fibers.

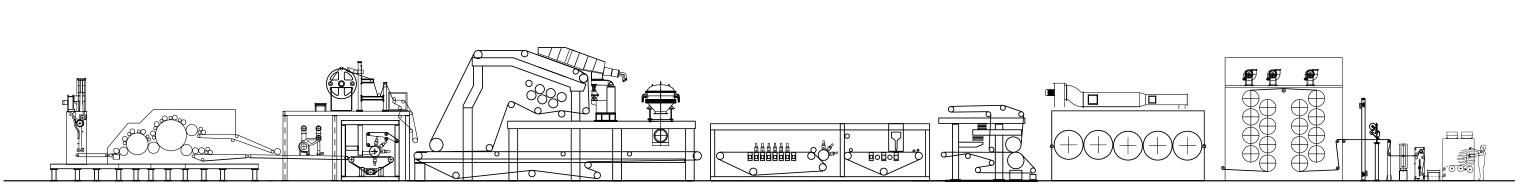

Wood pulp spunlace production line manufacturers have put enough effort into the design of the production line. Through careful planning and layout of the production process, manufacturers achieve an even distribution of wood pulp fibers during transportation, dispersion and shaping. At the same time, manufacturers also use advanced control systems to monitor the operating status of the production line in real time to ensure the coordination and stability of all links.

Wood pulp spunlace production line manufacturers also focus on quality control during the production process. Through regular testing and debugging, manufacturers ensure that various parameters of the production line are in optimal condition to ensure the tight integration of wood pulp fibers. The manufacturer has also established a strict quality management system and strictly controls every link to ensure product quality and stability.

Wood pulp spunlace production line manufacturers have also strengthened communication and cooperation with customers. Through in-depth understanding of customer needs and feedback, wood pulp spunlace production line manufacturers continue to optimize the performance and functions of the production line to meet customer requirements for product quality and performance.

As a professional wood pulp spunlace production line manufacturer, by strictly controlling raw materials, optimizing production line design, strengthening quality control, and strengthening communication and cooperation with customers, we ensure the even distribution and close integration of wood pulp fibers, and provide customers with High quality, high performance products.

How does the flushable (environmentally friendly) spunlace line supplier ensure the stability of the products produced by the flushable (environmentally friendly) spunlace line in the toilet flushing system?

With the increasing awareness of environmental protection, flushable (environmentally friendly) spunlace products are increasingly favored by the market. As a professional flushable (environmentally friendly) spunlace line supplier, we know that ensuring the stability of our products in the toilet flushing system is of great significance to meeting customer needs and promoting market development. Therefore, a series of measures have been taken to ensure product stability and reliability.

Pay attention to the material selection of the product. Suppliers of flushable (environmentally friendly) spunlace lines know that the quality of materials directly affects the performance and stability of the product. Therefore, raw materials that meet environmental protection standards are strictly screened, and advanced production processes and technologies are adopted to ensure that the products have good water resistance and corrosion resistance.

Continuous innovation and optimization in product design and production. Through in-depth understanding and research on toilet flushing systems, flushable (environmentally friendly) spunlace production line suppliers have designed product structures and shapes that are more in line with toilet flushing system requirements. At the same time, advanced molding technology and equipment are also used to ensure the dimensional accuracy and shape stability of the product.

The inspection and testing of products have also been strengthened. By simulating the actual operating environment and conditions of the toilet flushing system, flushable (environmentally friendly) spunlace line suppliers conduct rigorous testing and evaluation of the products to ensure that the products can maintain stability and reliability during use. At the same time, a complete quality management system has been established to strictly control every production link to ensure the stability and consistency of product quality.

Communication and cooperation with customers have also been strengthened. Flushable (environmentally friendly) spunlace production line suppliers have an in-depth understanding of customer needs and feedback, and promptly adjust product design and production plans according to market changes and customer needs to ensure that the products can better adapt to the requirements of the toilet flushing system.

As a professional flushable (environmentally friendly) spunlace line supplier, we ensure the safety of our products in toilet flushing systems by strictly controlling raw materials, innovating and optimizing product design, strengthening product inspection and testing, and strengthening communication and cooperation with customers. Stability and reliability provide customers with high-quality, reliable and environmentally friendly products.