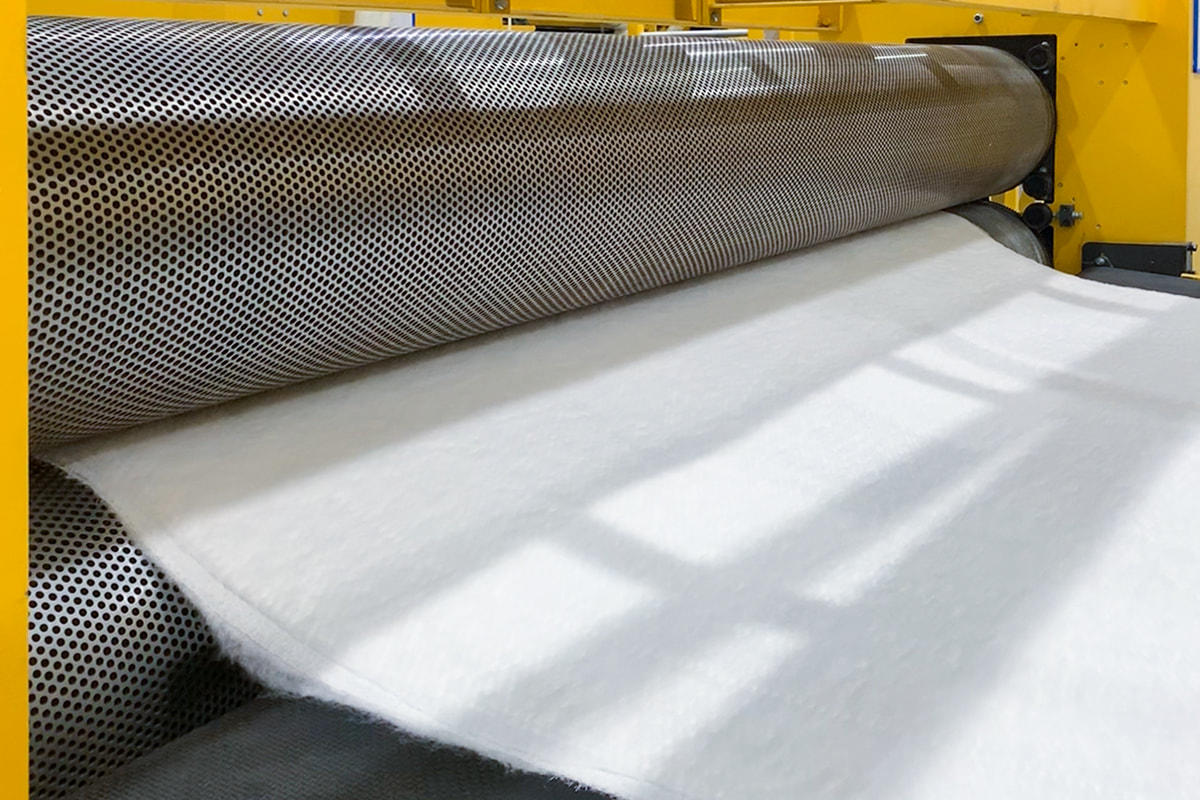

In the non-woven fabric manufacturing process, the carding machine plays a vital role, and its performance directly affects the uniformity, strength and quality of the fiber web. With its optimized card clothing configuration and drum dynamic design, the C30 high-speed carding machine can still maintain the stability of fiber processing under high-speed operation conditions, ensuring the continuity and consistency of non-woven fabric production. The core advantage of this equipment lies in the synergy of its modular card clothing system and precision drum structure, which enables it to adapt to different fiber characteristics while avoiding fiber damage and ensuring the uniform distribution of fiber web weight.

The core of the carding process is to decompose the fiber bundle into a single fiber state and form a uniform fiber web. When the traditional carding machine is running at high speed, the quality of the finished product is often affected by fiber scattering, uneven distribution or excessive damage. The C30 high-speed carding machine optimizes the density and angle of the card clothing arrangement to ensure that the fiber remains stable during the high-speed carding process. Its card clothing adopts modular design and can be flexibly adjusted according to fiber length, fineness and electrostatic characteristics. For example, for ultra-fine fibers, a higher density of card clothing is used to reduce fiber loss; for high-static fibers, special coatings are used to reduce charge accumulation caused by friction. This adaptive design not only improves the versatility of the equipment, but also significantly reduces the fiber breakage rate and ensures the integrity of the fiber web.

The drum dynamic design is another key factor in the stable combing of the C30 high-speed carding machine. The equipment adopts a multi-drum cooperative operation structure. The speed ratio and spacing between each drum are precisely calculated to ensure that the fiber is evenly stressed during the transfer process to avoid excessive stretching or accumulation. The dynamic balance design between the main cylinder and the working roller and the stripping roller allows the fibers to remain in an orderly arrangement during high-speed combing, reducing fiber entanglement or flower return. In addition, the drum surface is specially treated to reduce fiber adhesion, further reduce fiber damage, and improve combing efficiency.

In a high-speed production environment, the uniformity of the fiber web is crucial. The C30 high-speed carding machine monitors the fiber web status in real time through a closed-loop control system, dynamically adjusts the drum speed and spacing to ensure consistent weight. This intelligent adjustment not only reduces manual intervention, but also improves process stability, allowing the equipment to adapt to production requirements of different weights and fiber ratios. The modular design of the equipment facilitates maintenance and adjustment, reduces downtime, and improves production efficiency.

The technical value of the C30 high-speed carding machine is not only reflected in high-speed and stable carding, but also in its flexibility to adapt to diversified fiber production. Whether it is natural fiber, synthetic fiber, or special functional fiber, the equipment can achieve efficient carding through the optimized combination of needle clothing and rollers, meeting the high standards of non-woven fabrics in the fields of medical, sanitation, filtration, etc. Its design concept of combining precision engineering with intelligent control makes it a key equipment in non-woven fabric production, providing the industry with a reliable solution that takes into account both efficiency and quality.