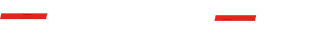

Three sections of beam combination structure body, more stable structure, high-quality thick steel plate welding, and multiple tempering heat treatment to eliminate internal stress, through the upper beam, side beam, lower beam finite element analysis, optimization of structural design, so that has a frequency of 2200 times / min under the effective vibration resistance, fatigue resistance, standard high-speed operation box structure, building block type combination, management and maintenance can be standardized and unified. The unique heat dissipation fin structure design of the box can be more effective heat dissipation, spindle, connecting rod and other internal parts of the box CNC ultra-precision machining to ensure stable operation and low noise, high-strength aluminum alloy needle beam, by finite element analysis, then heavy load conditions deformation, and optimize the design, high-strength magnesium alloy needle plate, needle hole arrangement confirmed by the needle plate simulation software test, reduce the needle stabbing needle marks, the same specification needle plate can be interchangeable Design, reduce the preparation board, airbag locking positioning, fast and convenient operation to replace the needle plate, and air source pressure protection, to prevent damage after the accidental loss of air, CNC drilling machine precision punching processing, trawl plate hole optional reaming, improve the finish, no burr, not easy to hang fiber

Scope of application: reinforcement and entanglement of various types of needle punching method nonwoven fabrics

Main specifications: working width: 1-16m, needling design frequency 2200n/min, walking speed up to 30m/min