In the long-standing and dynamic field of the textile industry, roller carding machines have become key equipment in modern textile production lines with their unique process characteristics and irreplaceable role. This article aims to explore in depth the working principle, key components and core role of roller carding machines in textile production, especially the exquisite craftsmanship in the fiber combing and blending process. By analyzing in detail how roller carding machines comb fibers from preliminary combing to forming a fine mesh fiber layer, we can better understand its importance in the textile industry.

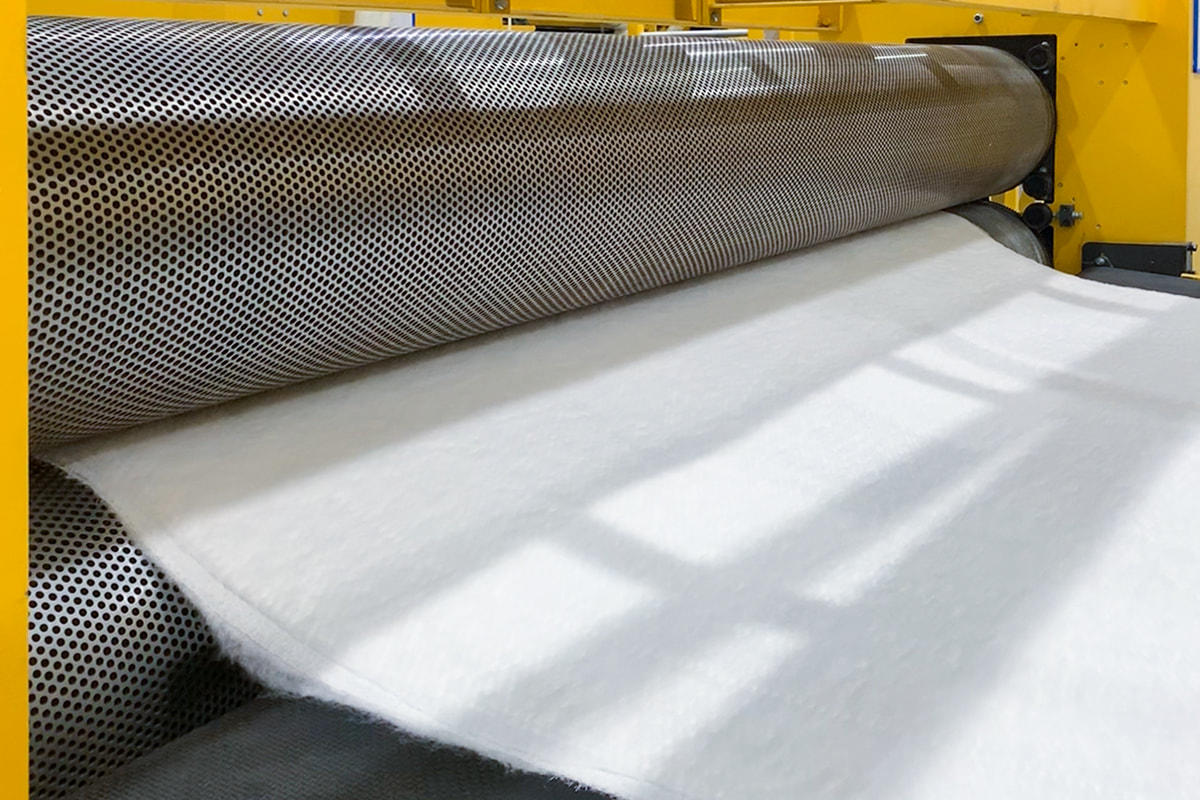

As the core equipment in the textile process, the core function of roller carding machines is to further refine, optimize and blend the preliminarily processed spinning raw materials to finally generate uniform fiber strips. This process involves multiple precise mechanical movements and physical actions, and its core components mainly include cylinders, doffers, working rollers and stripping rollers.

Cylinder: The cylinder is the key combing element in the roller carding machine, usually consisting of a high-speed rotating cylindrical drum and a needle cloth covering its surface. The centrifugal force generated by the high-speed rotation of the cylinder disperses and preliminarily combs the fibers, so that the fibers are broken down from blocks or bundles into single or short fibers.

Doffer: The doffer is located below the cylinder and is usually composed of a slowly rotating cylindrical drum and a needle cloth covering its surface. The main function of the doffer is to gently strip the preliminarily combed fibers from the cylinder to form a fine fiber web. The slow rotation of the doffer helps to ensure that the fibers are not damaged during the stripping process, while allowing the fibers to be evenly distributed on the doffer surface.

Working rollers and stripping rollers: The working rollers and stripping rollers are usually located downstream of the doffer, and the interaction between them further combs and strips the fibers to ensure that each fiber is fully combed and evenly distributed. The working rollers usually work in conjunction with the cylinder, while the stripping rollers are responsible for stripping the fibers from the working rollers in preparation for subsequent processes.

After the fibers are preliminarily combed by the cylinder, they are evenly distributed on the surface of the cylinder to form a thin fiber layer. This process is one of the key steps in the operation of the roller carding machine. It requires precise control of the speed ratio between the cylinder and the doffer to ensure that the fibers are fully dispersed and mixed during the combing process.

The centrifugal force generated by the high-speed rotation of the cylinder disperses and preliminarily combs the fibers. During this process, the fibers are decomposed from blocks or bundles into single or short fibers and evenly distributed along the surface of the cylinder. The configuration of the card clothing on the surface of the cylinder is crucial to the combing effect of the fibers. The density, shape and arrangement of the card clothing will affect the combing quality and mixing effect of the fibers.

Subsequently, the slow rotation of the doffer gently strips off this part of the fibers to form a thin layer of finer mesh fibers. The slow rotation of the doffer helps to ensure that the fibers are not damaged during the stripping process, while forming a uniform distribution of the fibers on the doffer surface. The card clothing configuration of the doffer is also important, which determines the residence time of the fibers on the doffer and the stripping effect. By reasonably adjusting the speed ratio and card clothing configuration between the doffer and the cylinder, it can be ensured that the fibers are fully mixed and evenly distributed during the combing process.

The combing effect of roller carding machine is affected by many factors, among which the precise control of the speed ratio between the cylinder and the doffer and the rationality of the card clothing configuration are particularly important.

The precise control of the speed ratio between the cylinder and the doffer is the key to ensure the combing effect of the fiber. The size of the speed ratio determines the residence time and combing degree of the fiber between the cylinder and the doffer. If the speed ratio is too large, the fiber may not be fully combed on the cylinder; if the speed ratio is too small, the fiber may stay on the doffer for too long, resulting in fiber damage or poor mixing effect. Therefore, in the design and operation of the roller carding machine, the speed ratio between the cylinder and the doffer must be precisely controlled to ensure the best combing effect of the fiber.

The configuration of the card clothing is also crucial to the combing effect of the roller carding machine. The density, shape and arrangement of the card clothing will affect the combing quality and mixing effect of the fiber. Reasonable card clothing configuration can ensure that the fiber is fully dispersed and mixed during the combing process, while avoiding fiber damage. In the design and manufacturing process of the roller carding machine, the appropriate card clothing configuration must be selected according to the nature of the raw materials and production requirements to ensure the best combing effect.

Roller carding machines require not only that the fibers are fully dispersed and mixed during the carding process, but also that the fibers are evenly distributed on the doffer. The realization of this goal depends on the interaction between the cylinder and the doffer and the rationality of the configuration of the card clothing.

Under the interaction between the cylinder and the doffer, the fibers are evenly distributed on the surface of the doffer, forming a fine mesh fiber layer. This process requires not only precise control of the speed ratio between the cylinder and the doffer, but also reasonable configuration of the card clothing to ensure that the fibers are not damaged during the carding process and achieve the best mixing effect. By reasonably adjusting the speed ratio and card clothing configuration between the cylinder and the doffer, it can be ensured that the fibers are evenly distributed on the doffer, providing high-quality fiber strips for subsequent processes such as drawing, roving, and spun yarn.

In order to ensure the long-term stable operation and the best carding effect of the roller carding machine, it must be regularly maintained and serviced. This includes cleaning the card clothing of key components such as the cylinder, doffer and working roller, replacing severely worn card clothing, and keeping the equipment lubricated and clean. Through regular maintenance and care, the service life of the roller carding machine can be extended, production efficiency can be improved, and the combing quality and mixing effect of the fiber can be ensured.

As a key equipment in the textile industry, the roller carding machine plays an important role in textile production with its precise combing process and efficient production capacity. Through in-depth analysis of the working principle, key components, fiber combing and mesh fiber layer formation process of the roller carding machine, and the importance of precise control and card clothing configuration, we can better understand its importance in the textile industry. With the continuous advancement of technology and the optimization of processes, roller carding machines will continue to play a greater role in the development of the textile industry and promote the textile industry to move towards higher quality and higher efficiency.