In the field of material processing, wet-laid web forming technology has become an important means of producing high-performance fiber materials due to its unique process advantages. As a core equipment, the wet-laid web forming machine's precise web forming capability directly determines the quality of the final product.

Working principle and core structure of wet-laid web forming machine

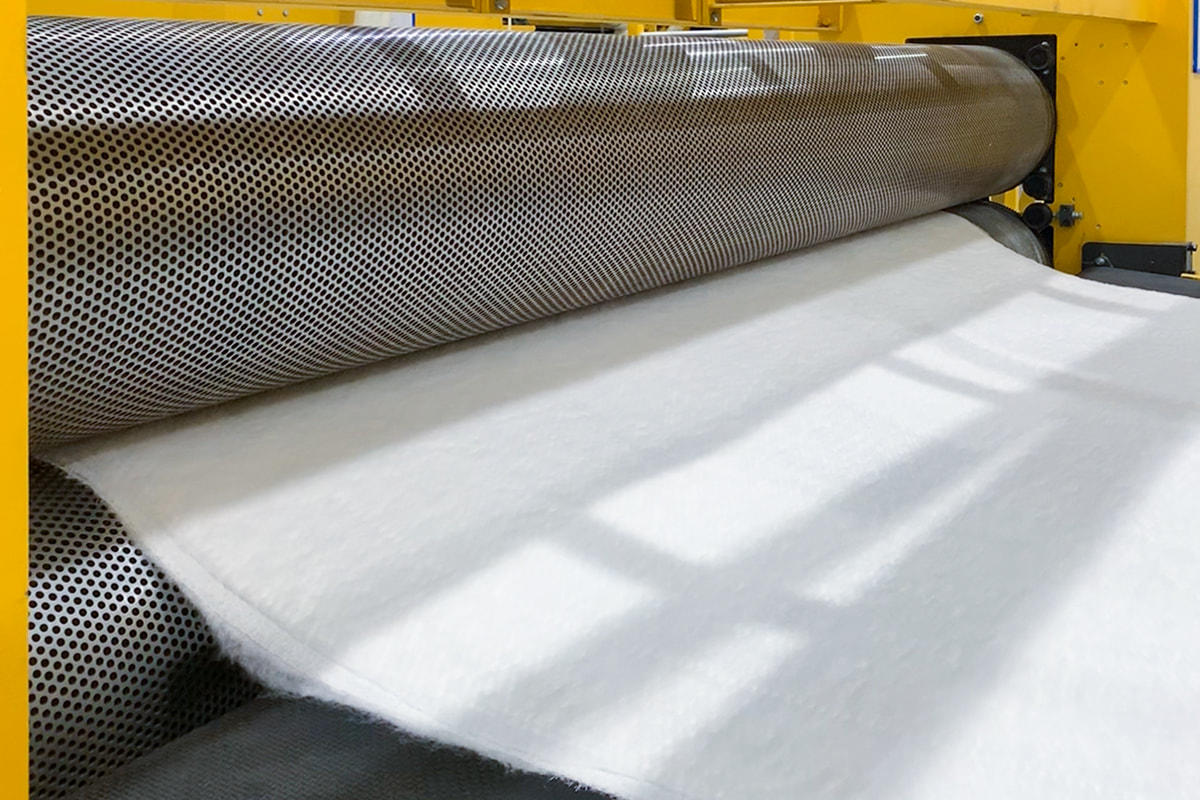

The working principle of the wet-laid web machine is based on fluid mechanics and fiber suspension theory. It disperses the fiber raw materials in water to form a uniform fiber suspension, and then uses mechanical, gravity and vacuum suction to dehydrate and deposit the fibers on the moving mesh curtain, eventually forming a continuous fiber web. The whole process can be divided into stages such as fiber dispersion, transportation, dehydration and reinforcement.

Its core components mainly include the following parts: first, the slurry preparation system, which is responsible for mixing the fiber raw materials with water, and through stirring, dispersing and other operations, fully dispersing the fibers to form a suspension with appropriate concentration; second, the forming system, in which the mesh curtain moves at a uniform speed driven by the transmission device, and the fiber suspension is evenly sprayed on the mesh curtain through the headbox. As the mesh curtain moves, the fibers are dehydrated and deposited under the action of gravity and vacuum suction; third, the dehydration system, which consists of a vacuum box, a pressing roller, etc., further removes moisture from the fiber web and improves the bonding force between the fibers; and finally, the hot air drying system, which uses hot air to dry the fiber web to reach the specified moisture content. Each system works together to ensure that the fibers can be evenly webbed in a predetermined manner.

Analysis of key parameters affecting web uniformity (fiber concentration/dewatering rate/net curtain speed)

l Fiber concentration

Fiber concentration is one of the key factors affecting the uniformity of web formation. In the wet web forming process, if the concentration of the fiber suspension is too high, the fibers are easily entangled and agglomerated with each other, resulting in defects such as uneven thickness and holes in the web; if the concentration is too low, it will reduce production efficiency and increase the energy consumption of subsequent dehydration and drying. Generally speaking, different fiber materials and product requirements correspond to different optimal fiber concentration ranges. For example, when producing paper materials, the fiber concentration is usually controlled between 0.1% and 1.5%; while for the production of high-performance nonwovens, the concentration may be around 0.3% to 2%. Accurate control of fiber concentration requires comprehensive adjustment based on the type, length, fineness of the fiber and the operating parameters of the equipment.

l Dehydration rate

The dehydration rate has a significant impact on the quality of the web. If the dehydration is too fast, the fibers will be quickly fixed before they are fully spread on the mesh, which can easily cause uneven fiber distribution; if the dehydration is too slow, it will extend the production cycle, affect production efficiency, and may cause secondary flocculation of the fibers in the suspension. The dehydration rate is mainly affected by factors such as vacuum degree, pressing pressure, and mesh structure. By reasonably adjusting the vacuum degree of the vacuum box and the pressure of the pressing roller, and optimizing the air permeability of the mesh, the dehydration rate can be accurately controlled, thereby ensuring the uniformity of the fiber web.

l Net curtain speed

The screen speed is closely related to the fiber deposition process. If the screen speed is too fast, the fiber suspension will stay on the screen for too short a time, and the fibers will not have enough time to deposit evenly, resulting in insufficient web thickness and poor uniformity. If the screen speed is too slow, the fibers will be excessively deposited, resulting in a thick fiber web or even clogging the screen. In addition, the screen speed must match the stock supply speed of the headbox to maintain a stable web formation process. In actual production, the screen speed needs to be accurately adjusted according to the quantitative requirements of the product, the fiber characteristics, and the production capacity of the equipment to ensure that the fibers can be evenly and stably formed into a web.

Application practice of wet-laid web machine in the field of special materials

l Filter material

In the field of filter material production, wet-laid web forming machines play an important role. By utilizing its precise web-forming characteristics, filter paper, filter cloth and other products with different pore structures and filtration efficiencies can be produced. For example, filter paper for automobile engine air filters requires good air permeability and high filtration accuracy. By controlling the various parameters of the wet-laid web forming machine, the fibers can form a uniform pore distribution during the web-forming process, effectively intercepting dust and impurities in the air while ensuring the strength and durability of the filter paper. In addition, high-temperature filter materials used in the field of industrial dust removal can also be made into fiber nets with special structures through wet-laid web forming technology, and then after subsequent processing, they can meet the filtration needs under different working conditions.

l Medical protective materials

With the development of the medical industry, the requirements for medical protective materials are getting higher and higher. The spunlace nonwoven fabrics produced by the wet-laid laminating machine are widely used in medical dressings, surgical gowns, masks and other products because of their softness, breathability and strong liquid absorption. When producing the composite layer of meltblown cloth and spunlace cloth for medical masks, the fiber distribution and thickness of the spunlace cloth are precisely controlled through the wet-laid laminating technology, so that it is perfectly combined with the meltblown cloth, which can not only ensure the protective performance of the mask, but also improve the comfort of wearing. At the same time, the wet-laid laminating technology can also be used to produce medical protective materials with special functions such as antibacterial and antistatic, providing more reliable protection for medical safety.

l Aerospace Composites

In the field of aerospace, the requirements for lightweight, high strength and high performance of materials are extremely stringent. The wet-laid web machine can make high-performance fibers such as carbon fiber and glass fiber into uniform prepreg blanks, laying the foundation for subsequent composite material molding. By precisely controlling the fiber arrangement and distribution during the web-forming process, the final composite material can have excellent mechanical properties and dimensional stability. For example, when manufacturing structural components such as aircraft wings and fuselages, composite materials produced using wet-laid web-forming technology can effectively reduce component weight and improve fuel efficiency, while ensuring the strength and reliability of the structure, providing key support for the development of the aerospace industry.

Equipment optimization direction: from energy consumption control to intelligent upgrade

l Energy consumption control

During the operation of the wet web machine, pulp preparation, dehydration, drying and other links all consume a lot of energy. In order to reduce energy consumption, optimization can be carried out from multiple aspects. In the pulp preparation system, efficient stirring and decomposition equipment is used to reduce energy consumption in the fiber dispersion process; in the dehydration system, the dehydration efficiency is improved by improving the structure of the vacuum box and the pressing roller, and the energy required for vacuum suction and pressing is reduced; in the drying system, new energy-saving drying technologies such as infrared drying and heat pump drying are used to improve thermal energy utilization and reduce energy consumption. In addition, rationally optimizing the operating parameters of the equipment and achieving efficient operation of the equipment is also an important way to reduce energy consumption.

l Intelligent upgrade

With the development of Industry 4.0 and intelligent manufacturing, the intelligent upgrade of wet-laid web machines has become an inevitable trend. By introducing sensors, the Internet of Things and big data analysis technologies, real-time monitoring and precise control of equipment operating status and process parameters can be achieved. For example, a concentration sensor is installed at the headbox to monitor the concentration of the fiber suspension in real time, and the slurry supply and water volume are automatically adjusted through the feedback control system to ensure stable fiber concentration; the visual inspection system is used to conduct online inspection of the web quality. Once defects such as uneven thickness and holes are found, the equipment parameters are adjusted in time or an alarm signal is issued. In addition, based on artificial intelligence algorithms, the analysis and learning of historical production data can predict equipment failures, optimize production processes, improve production efficiency and product quality, and realize the intelligent and automated production of wet-laid web machines.