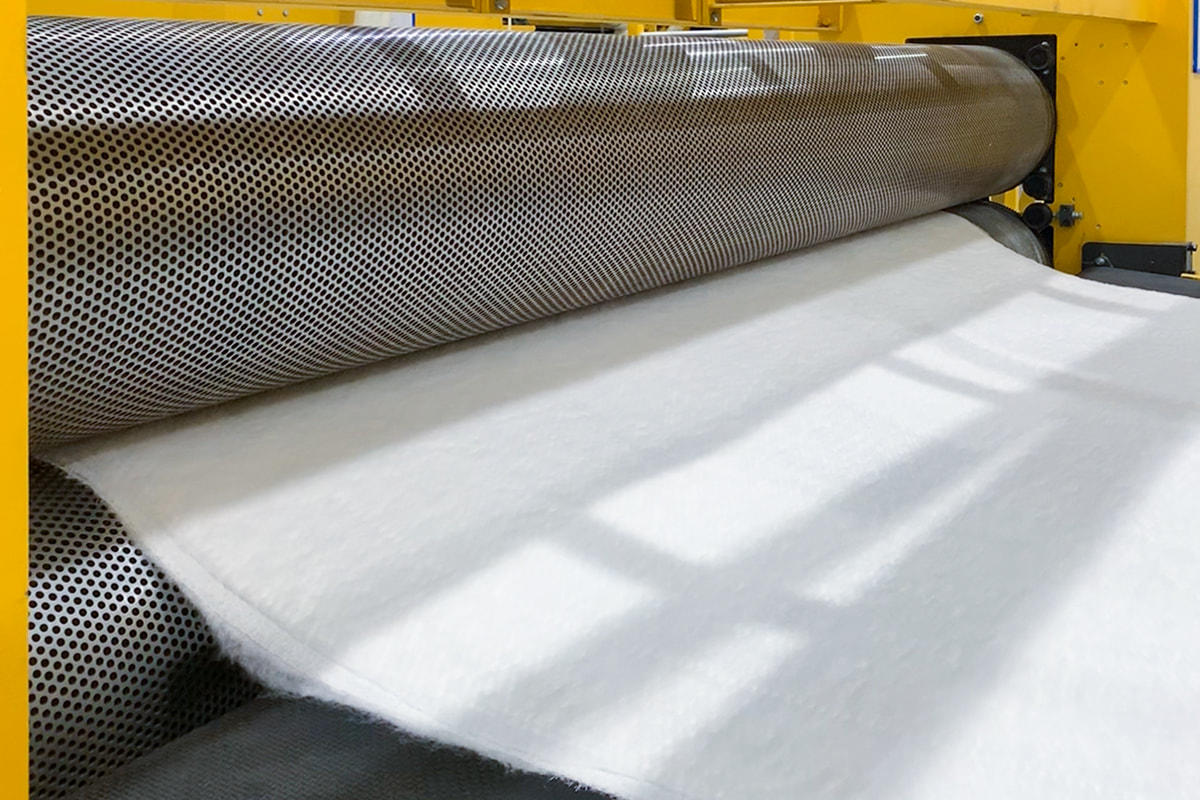

In the production process of non-woven fabrics, the diversity of fiber raw materials poses a severe challenge to the web laying process. Different fibers (such as polyester, polypropylene or composite materials) have significant differences in gram weight, length, electrostatic properties and fluidity. Traditional web laying equipment often finds it difficult to balance the requirements of high-speed operation and uniform web formation. The CL30 high-speed cross-lapping machine achieves high adaptability and stable web laying for multiple fiber raw materials through the synergy of parametric module design, mechanical structure optimization and intelligent detection system, providing reliable technical guarantee for non-woven fabric production.

One of the core technologies of CL30 is its parametric modular control system, which can quickly adjust the web laying trajectory according to the physical properties of different fibers. Due to its high rigidity, polyester fiber is prone to uneven dispersion due to inertia during high-speed web laying, while polypropylene fiber is prone to entanglement due to electrostatic effects. In response to these differences, the process database of CL30 presets the optimization parameters of multiple fibers. The operator only needs to call the corresponding formula, and the equipment can automatically adjust the web laying speed, swing amplitude and web laying angle. For example, for high-flow composite fibers, the system will appropriately reduce the web laying speed and increase the cross angle to avoid fiber scattering; while for short fibers or ultra-fine denier fibers, the airflow auxiliary device is adjusted to ensure that the fibers are evenly distributed during the conveying process. This flexible adjustment capability not only shortens the production changeover and debugging time, but also significantly reduces the process fluctuations caused by raw material switching.

The mechanical stability of the web laying machine directly affects the uniformity of the fiber web. Especially when running at high speed, the vibration of the equipment can easily cause horizontal stripes or uneven weight of the fiber web. CL30 effectively suppresses the interference caused by mechanical vibration through the optimized design of the overall rigid structure. Its frame adopts high-precision welding technology and dynamic balance calibration, and key transmission components (such as web laying head guide rails and servo drive systems) are optimized by finite element analysis to ensure extremely low deformation in high-frequency reciprocating motion. In addition, the equipment adopts a modular assembly concept to reduce the risk of loosening of the connection parts and further improve the operating stability. This structural design enables CL30 to maintain the stability of the web laying process even at the highest operating speed, avoiding fiber web defects caused by mechanical jitter.

To ensure the continuous stability of the web laying quality, the CL30 is equipped with an intelligent detection system, which monitors the weight distribution, thickness and fiber orientation of the fiber web in real time through high-precision sensors. The system compares the collected data with the preset process parameters. Once a deviation is detected (such as excessive weight or fiber accumulation), it will be immediately fed back to the control center to dynamically adjust the web laying parameters. For example, if the weight on the right side of the fiber web is detected to be too high, the system will automatically reduce the web laying swing amplitude on that side and adjust the conveyor belt speed to achieve synchronous optimization of longitudinal and transverse uniformity. This closed-loop control mechanism not only solves the hysteresis problem of traditional manual adjustment, but also significantly reduces the waste of raw materials and the frequency of equipment downtime. It is especially suitable for high-end non-woven fabric production in the fields of medical and filtration, which have strict uniformity requirements.

The parametric module, rigid structure and intelligent detection system of the CL30 do not operate in isolation, but are coordinated and optimized through a highly integrated control platform. When switching fiber raw materials, the stability of the mechanical structure provides a physical basis for parameter adjustment, while the intelligent detection system ensures the precise execution of process parameters in actual production. This multi-level technology integration enables CL30 to adapt to the diversified production needs from conventional sanitary materials to high-performance composite non-woven fabrics.

From an industrial perspective, the highly adaptable design of CL30 has greatly reduced the equipment investment and operation and maintenance costs of non-woven fabric manufacturers. Traditional production lines often require special equipment for different raw materials, while CL30 can cover the efficient production of multiple types of fibers with a single device, while reducing resource consumption in the debugging and quality control links. More importantly, its stable output of high-quality fiber webs provides a guarantee for the performance consistency of downstream products (such as medical protective clothing, automotive interiors, etc.), indirectly improving the market competitiveness of end products.